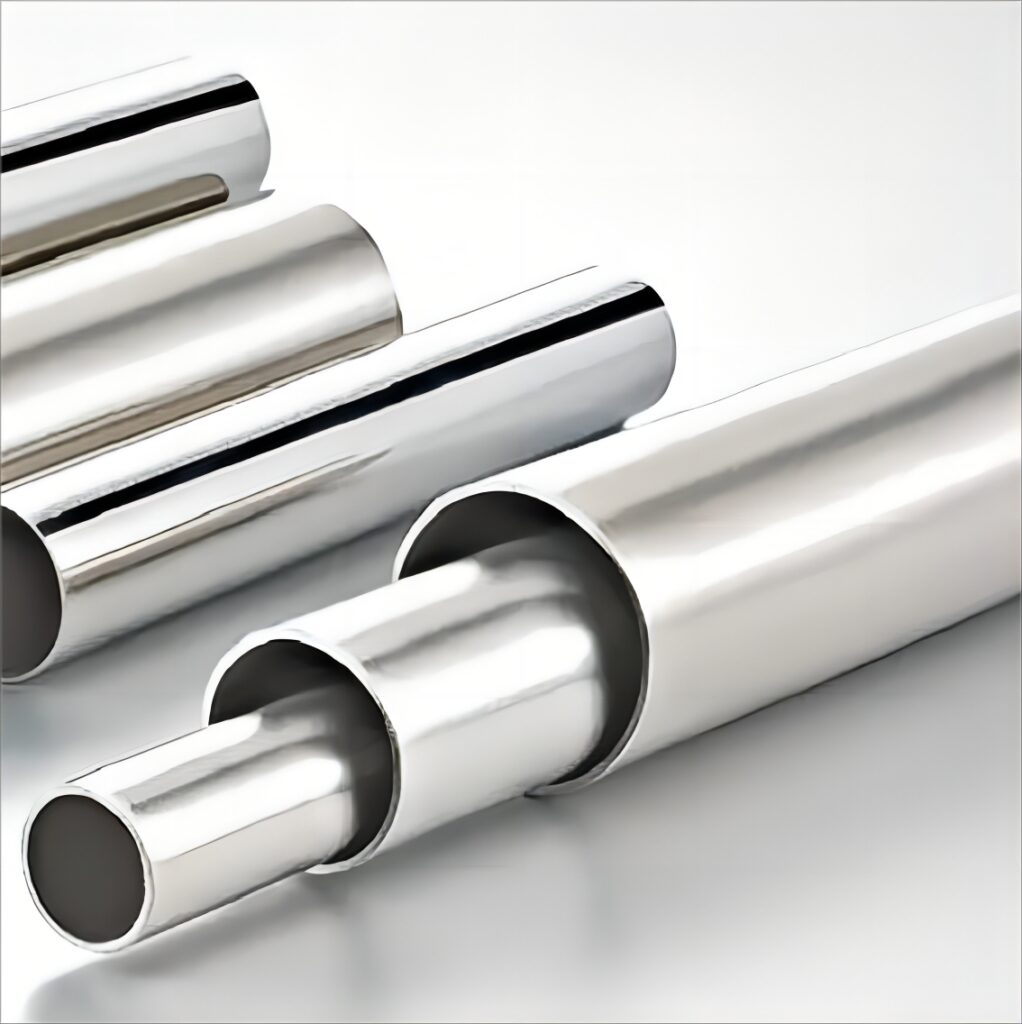

Monel 400 is a nickel-copper alloy that is known for its excellent corrosion resistance and high strength. It is composed of approximately 67% nickel and 23% copper, with small amounts of iron, manganese, carbon, and silicon. Monel 400 exhibits a unique combination of properties that make it suitable for various applications, especially in environments where corrosion resistance is crucial. Let’s delve into its properties and applications in more detail:

- Corrosion Resistance: Monel 400 offers exceptional resistance to a wide range of corrosive media, including seawater, sulfuric acid, hydrofluoric acid, and alkaline solutions. It is particularly resistant to chloride-induced stress corrosion cracking, making it ideal for marine and chemical processing applications.

- High Strength: Monel 400 possesses good mechanical properties, including high tensile strength and excellent toughness at both low and high temperatures. This alloy can withstand elevated temperatures and pressures, making it suitable for applications that require strength and reliability.

- Thermal Stability: Monel 400 exhibits good thermal conductivity and low thermal expansion characteristics. It maintains its mechanical properties over a broad temperature range, making it suitable for applications involving high temperatures and thermal cycling.

- Excellent Weldability: Monel 400 can be readily welded using various techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). This allows for easy fabrication and construction of Monel 400 components.

- Resistance to Erosion and Cavitation: Monel 400 demonstrates excellent resistance to erosion and cavitation damage, making it suitable for pump and valve components in industries such as oil and gas, chemical processing, and marine engineering.

- Low Magnetic Permeability: Monel 400 has low magnetic permeability, which makes it ideal for applications that require non-magnetic materials. It is commonly used in electronic and electrical components, including switchgear and magnetically sensitive devices.

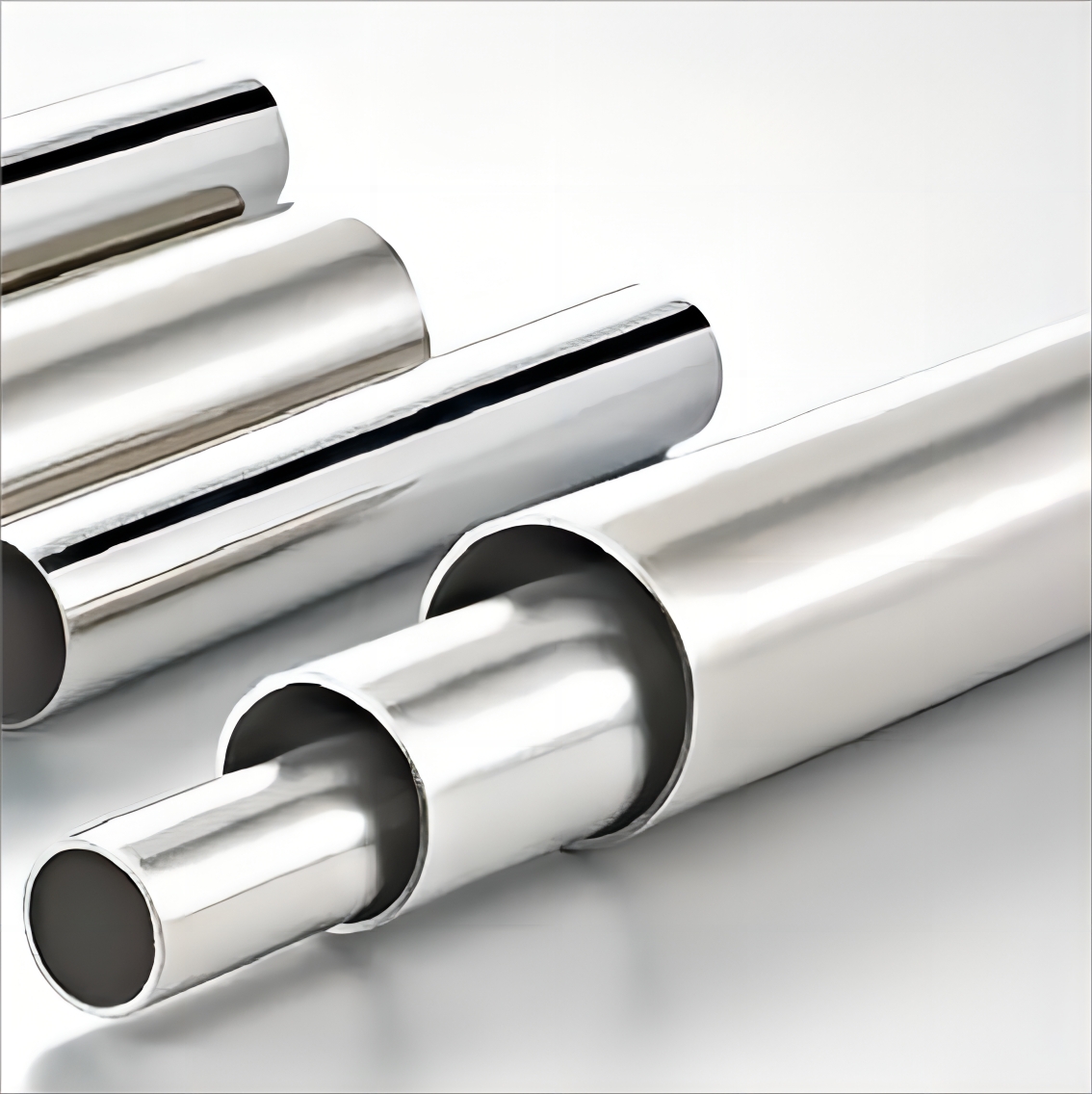

- Applications: Monel 400 finds applications in various industries, including:

- Marine Engineering: Shipbuilding, offshore oil and gas platforms, and seawater piping systems.

- Chemical Processing: Reactors, heat exchangers, pumps, valves, and piping systems.

- Aerospace: Aircraft fuel tanks, components, and fasteners.

- Oil and Gas: Downhole equipment, valves, pump shafts, and drilling tools.

- Power Generation: Steam generators, feedwater heaters, and turbine components.

- Electronics: Electrical connectors, switchgear, and sensor housings.

In conclusion, Monel 400 is a versatile alloy with exceptional corrosion resistance, high strength, and thermal stability. Its unique combination of properties makes it well-suited for a wide range of applications across multiple industries. Whether it’s marine engineering, chemical processing, aerospace, or electronics, Monel 400 continues to be a reliable choice for demanding environments.